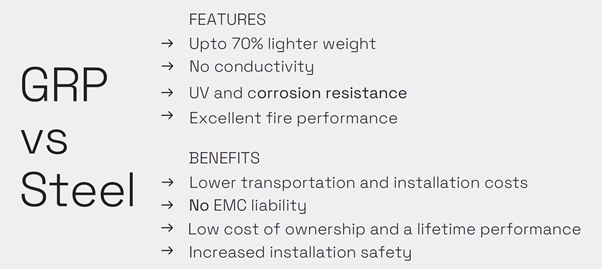

GRP vs Steel, by Mita

.jpg?width=140&height=140&ext=.jpg)

David Bryan

UK GRP Account Manager, Mita

Did you know that there is an alternative for steel which is more durable and less hassle to handle?

Discover GRP and its unique benefits for cable support, and our brand, MitaR GRP.

What is GRP?

GRP or FRP stands for Glass/Fiber Reinforced Polymer. It is a man-made resin-based material, reinforced with glass.

The polymer itself is extremely strong. It is resistant to most chemicals, stretching and shrinking, mildew and abrasion. When it is reinforced with glass (through a process called pultrusion) it becomes a structural polymer resistant to fire and highly corrosive environments.

Furthermore, it does not conduct heat. It has extra durability to adverse weather conditions and has UV stability which makes it an excellent candidate for outdoor applications, such as wind power substations in the middle of the sea.

GRP cable support

Cable support is the backbone of any building engineering project. Wherever there is a structural development, cable support is there to facilitate electrification, signaling and data.

Given this importance, GRP cable support systems possess unique properties which provide as much structural strength as a stainless steel installation , and can resist many corrosive environments, particularly where conditions indicate that conventional materials may not provide an economic service life.

A long standing brand: MitaR and its supported applications

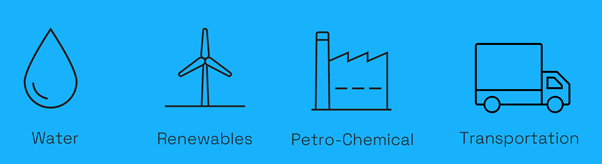

MitaR GRP, designed and manufactured in the UK, is now powered by ECA Commercial Associate Wibe Group. The offer includes a complete GRP cable support system range specifically designed for harsh and corrosive environments ensuring a sustainable installation through its lifetime.

Serving the transportation, onshore and offshore power, water and waste management, chemicals, pharmaceutical industries and many more, Mita GRP stands for “peace of mind” with its “fit and forget” solutions for generations to come.

Working with GRP

Another particularly useful feature of the MitaR GRP system is its ability to be integrated with the Bentley Raceway and Cable Management Building Information Modelling (BIM) tool.

This provides a complete layout, routing and material estimating function in a single, integrated system. It can be applied from the initial concept design through to detailed design and construction. A user can create an accurate 3D model of the cable troughing route, making it easy to ensure that adequate space and clearances are available in confined locations, and for the detailed design and material requirements to be quickly and easily produced.

In conclusion, MitaR GRP is a non-hazardous, inert product. It is lightweight and can be manually handled without difficulty, unlike concrete and steel. In contrast to steel, GRP does not have to be deburred or given edge treatment before fitting, saving time and further reducing labour costs. During installation, any cutting, drilling, bonding and jointing can be easily undertaken and will not give rise to a hazardous situation, with any dust kept to a minimum.

.jpg?width=140&height=140&ext=.jpg)

David Bryan

UK GRP Account Manager, Mita

Related Articles

VEGAS LED Strip

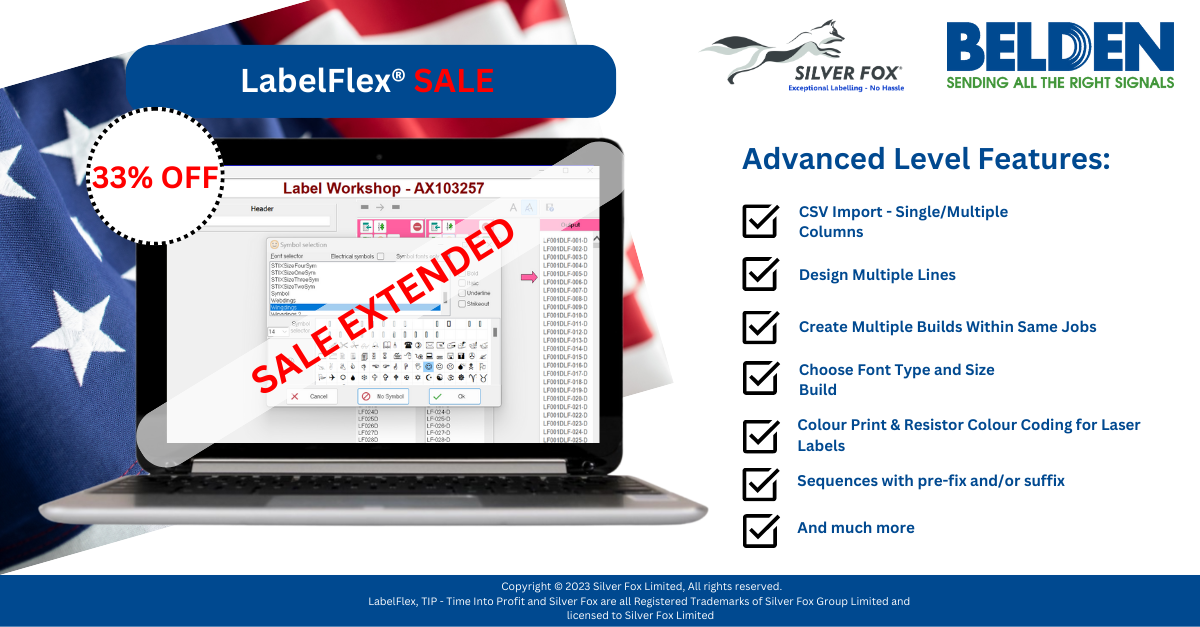

Next-level labelling with Multicomp Pro® Advanced Level Software

Silver Fox and Belden LabelFlex® Software

Solar PV Test Equipment

ESP, a Scolmore Group company

Network Rail approval for Sonel fault loop impedance meter

Schneider Electric launches EcoStruxure™ Asset Advisor

ECA Commercial Associate marks 100 years

Aico promote training and education with Mobile Units

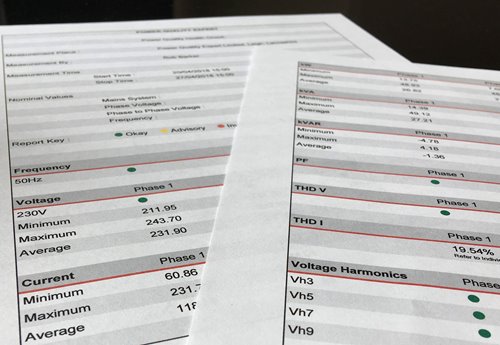

Power Quality Health Check App to Help Assess Live Harmonic Measurements

Learn about the Sonel MPI-540 series

Power Quality Health Check - Power Quality Analysis and Reports

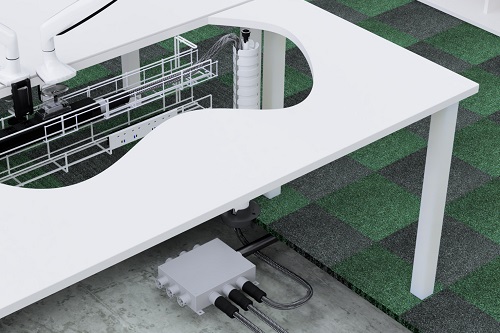

PowerConnect - A new standard in underfloor power distribution

Sanitising environments, surfaces and objects using Ozone

Test Instrument Solutions: EVSE testing on the road

Weatherguard: built to last

Is your cable management 18th Edition compliant?

Embrace the change with ASCOT Electrical Heating

Save on business energy bills with EnergyBillKill

Commitment at every level

Safer antimicrobial trunking solutions

Read ECAtoday Spring 2020 now!

Copyright © 2024 Electrical Contractors Association Ltd

.jpg?width=970&height=90&ext=.jpg)

3-(1).jpg?width=8164&height=5443&ext=.jpg)

.png?width=750&height=391&ext=.png)

.png?width=1200&height=627&ext=.png)